A long standing dream of the museum’s is to see the return of coupled Sydney P class trams. This has not been a possibility since 1960 and with only a select number of cars sold off for reuse instead of burning, options have been limited. At various points, plans included a possible de-conversion of a derelict PR1 No. 1517 back into a P car, and in 1999 a very weathered P 1501 was acquired from Lightning Ridge for potential restoration. In early 2010 however, the museum was able to acquire P 1729; a resident at the Canberra Tradesmen’s Union Club since 1981.

No. 1729 entered service on 26 February 1929. Later the same year it was decorated for the opening of the new promenade on Campbell Parade, Bondi on 21 December 1929. It was the seventh P car disposed of and the first to be sold, on 11 November 1958. Its body was sold to a caravan park in Braidwood. In 1980 it was bought by the Canberra Tradesmen’s Union Club and was installed in the club, on W2 trucks, during the following year. The seats in a number of compartments, which had been removed before or after the car was sold from Randwick, were replaced by new ones to the original design, made by the club’s carpenters. Over the years it has been a venue for eating and drinking by club members and visitors. More importantly, it has been under cover; protected from the elements. Of course the replacement of mechanical and electrical equipment represents a significant challenge, but a body in good condition is a very good start.

January 2010

The decision by the club to dispose of 1729 only came to the notice of the Museum when removal of the trams from the club was a little over a week away. Agreement was finally reached for the Museum to obtain the car on 19th January, after part of the club’s southern wall had been temporarily removed, as had a street lamp which was in the way. Once clear of the building they were lifted by crane onto a semi-trailer, which took them to a holding yard in Queanbeyan for an overnight stay. P 1729 was reunited with its W2 bogies on the morning of 20 January, and was brought by Australian Train Movers to Sydney.

February 2012

The museum has received a $50,000 grant under the 2011-2013 NSW Heritage Grants program, to assist with the restoration of P 1729. The car has been moved to the second position from the rear of road 7 in the Display Hall from where it can be seen by the public. This is to comply with the grant’s terms.

April 2012

Much progress has been made on the removal of modifications added by the club such as perspex door and window infills, tables, shelving, wiring, interior lamps and audio fittings, in addition to the removal of all carpet, underlay and two layers of Masonite which had been glued and nailed to the original flooring of the car. On removal of this material the original floor was found to be in sound condition.

Geoff Spaulding has removed the old upper fixed glass from the car sides, and is undertaking the tedious job of removing the original plate glass lower window panes to make way for the replacement toughened glass. Broken glass in some of the window cavities is a hazard and an obstruction and further slows the removal process. Replacement ‘Smoking’, etched glass and plain etched glass has been obtained from a specialist glass supplier for the fixed side top window panes, and replacement toughened glass, drilled to allow for fitting of the aluminium cast lifters has also been obtained.

Several of the cross bench seats are replicas, fitted by the carpenters at the Canberra Tradesmens Union Club when the car was installed in the bistro. Although they are authentic in looks, they were not built in the same tongue and groove manner of the remnant originals. Steel brackets were fitted to attach the frame to the top seat nosing, and tie rods were omitted. For the car to be used it is essential these tie rods are replaced. Warren Howlett secured the replacement threaded rod, Warrington Cameron has had replacement brass outer frame castings made, Martin Pinches has removed filler from the original tie rod holes in the side pillars, and removed seat back slats to enable holes to be drilled through the steel brackets and timber seat frames for the tie rods to be fitted.

January 2013

The old roof canvas of P 1729 has been stripped and replaced by Geoff Spaulding with assistance from Howard Clark, Vic Solomons and a CSO worker. Geoff finished repairing a few damaged roof boards, plugging all the sprinkler head and cable duct holes that date from time at the Canberra Tradesmen’s Union Club. They also sanded the roof prior to its re-canvassing.

March 2013

Geoff Spaulding, and Howard Clark are repairing and priming the cab framing and windows of Sydney P 1729 while Vic Solomons, Michael Kerry and two CSO workers have made good progress on the removal of old paint and the sanding of the bodywork

April-May 2013

Our painting team and a CSO worker have started work on priming and repainting P 1729. Meanwhile new footboards have been installed by Geoff Spaulding.

September 2013

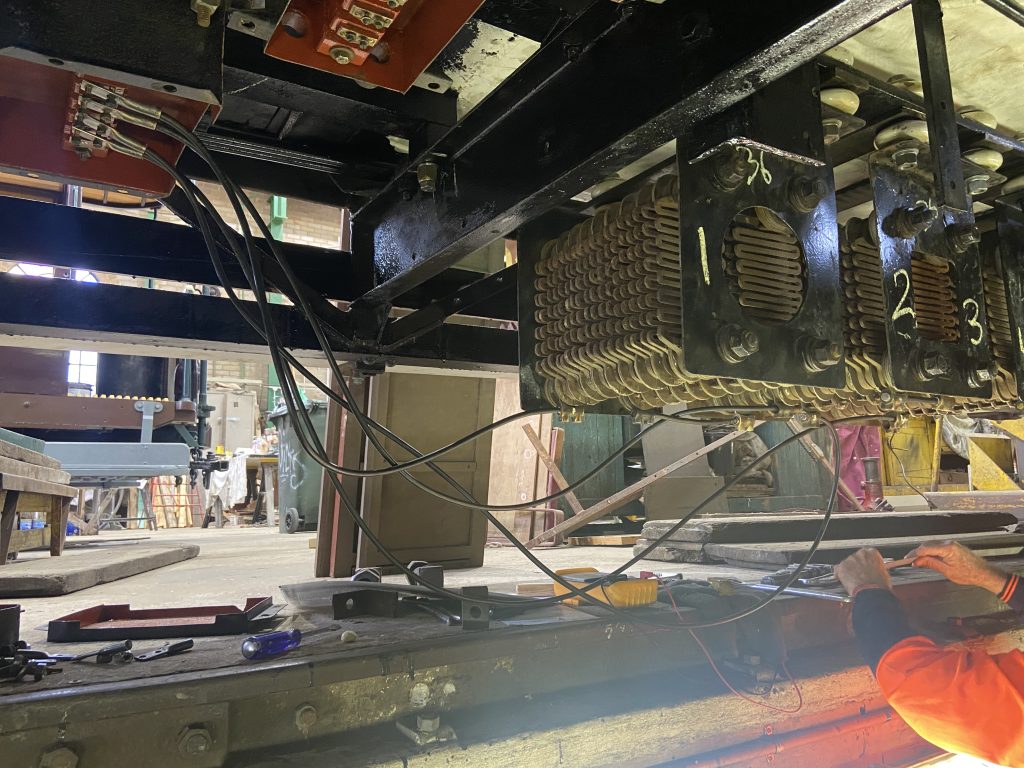

With the body restoration of this car nearing completion, it was moved into the workshops on the 7th of September 2013 to start on the electromechanical fit out. The workshop’s electrical sector have been working for some time on the PC5 auto-acceleration controller and other equipment required. Two sets of equipment are being refurbished so that that PR1 1573 will also eventually take its place in the restoration hall and be fitted out.

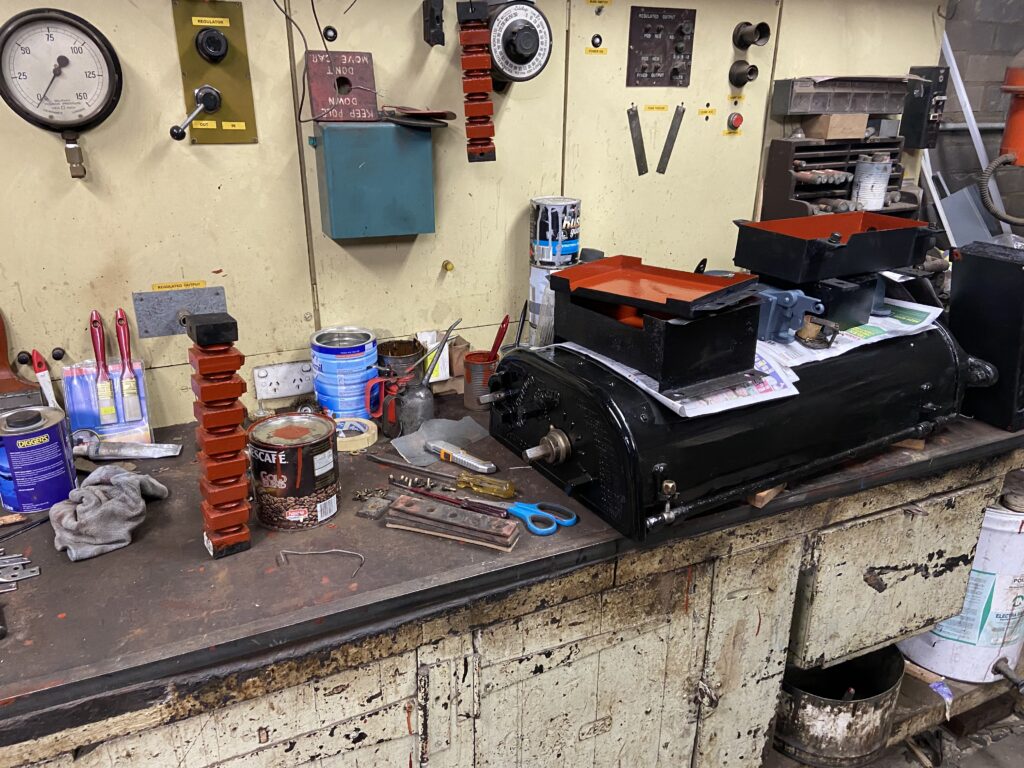

The following photo shows the refurbished ‘PC5’ controller that will be fitted to 1729. This unit is effectively new, having been used in a rig for training new tramway fitters on the equipment.

September 2014 – Postponement of works

Various issues have seen work on this car halt. Illness of a volunteer who was working on the body has seen body work mostly cease and an issue in New Zealand has delayed the fabrication of the new trucks required. As a result the car was removed from the workshop and Ballarat 37 returned. Body works on P 1729 will continue in Road 8 for the time being.

October 2018 – P type bogies arrive from New Zealand

Over the past couple of years, the Christchurch Tramway Historical Society workshops at Ferrymead have been working on constructing Sydney No. 9 bogie trucks used exclusively under P class trams, for the express intention to be used under P 1729 and PR1 1573. Using a complete bogie SPER had obtained from the Seashore Trolley Museum in the US as a pattern, along with drawings from the SPER archives, they constructed 2 complete bogies and completely refurbished the ‘original’ one. These were shipped over to Loftus in late October 2018.

November 2018

The storage of these bogies became somewhat of a problem. So it was decided that 2 of the bogies would go immediately under P 1729. On the 10th November, 1729 replaced PCC 1014 in the workshop for the day; it was lifted and the Melbourne W2 bogies it previously sat on were replaced by the No. 9 trucks. Once completed, the P was out of the workshop and back to being stored in Road 8 the same day. The third bogie will be stored elsewhere until PR1 1573 returns from off site storage. It is currently sitting on another Sydney No. 9 truck at one end, and a Melbourne W2 truck on the other end.

The current work queue in the workshop means it will be some time before more work can be done on 1729 towards making the car operational again.

October 2019

Contract heritage carpenter Mick Kinsella has been working on completing some unfinished tasks to the car’s bodywork. He has applied more strips of canvas to the back of one roof valence and has installed the full set of upper fixed glass window panels.

March 2022

5th March

Since 1729’s acquisition, the museum’s other unrestored P class tram No. 1501, has been kept aside as a spare; placed in offsite storage in Victoria. It still retains many vital components that are lacking on 1729 including brake rigging. Recently the opportunity was taken to move it to Loftus to facilitate the removal of these items. It has been placed on a pair of W2 shop trucks and stored on Road 12 in the depot yard. Once parts removal is complete, P 1501 will be moved to off-site storage at Londonderry.

12th March

Work has progressed on removing the parts needed from P 1501, the complete P 1729’s restoration. The workshop crew has already started overhauling items such as the motor cut out box and motor-trolley connection box. The removal of brake rigging continues.

April 2022

16th April

Frank Cuddy has made quick progress on the overhaul of the motor cut out box designated for 1729 with other electromechanical equipment to follow suit.

30th April

Rapid progression has been made on renewing the individual brake rigging pieces that were removed from P 1501, with rusty components cleaned up and painted with rust converter to prevent further corrosion.

May-June 2022

The past two months have seen a steady stream of work continue on overhauling the items needed to complete 1729’s electromechanical fit out. By the time the car re-enters the workshop, everything should be immediately ready for installation.

July 2022

The workshop crew has been enthusiastically installing the operational equipment allocated for 1729 whilst it’s still in situ in Road 8. Mounting brackets, Westinghouse controllers and new hand brake staffs have been refitted to both drivers cabs whilst the renewed brake rigging components from 1501 continue to be progressively installed underneath the car.

October 2022

P 1729 was finally moved back into the workshop on 8th October 2022 to enable to installation of hardware and brake rigging under the car. The first task will be to install the Tomlinson couplers designated for the car to allow for easier shunting.

November 2022

12th November

Ed Terry and Daniel Callender have cleaned and applied protective paint to the underfloor of the cabs before the couplers are installed.

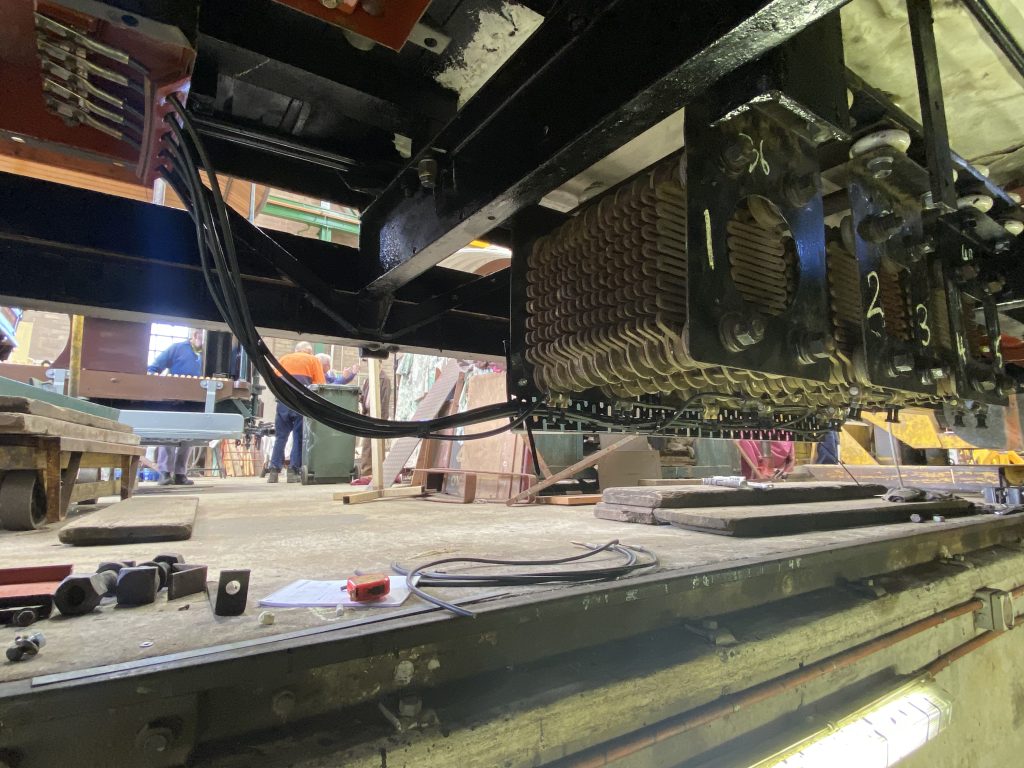

[1]

[1] [2]

[2]23rd November

The south cab coupler bracket is being cleaned in preparation for repainting and reinstallation. Similar work will be undertaken on the north cab bracket.

26th November

Work to complete the car’s roof canvasing is underway. This is being done by our heritage contract carpenter Mick Kinsella.

December 2022

10th December

Work on the roof canvas is progressing well with another layer of navy dressing applied to the recently laid canvas. A choke coil is also being overhauled for eventual placement on the roof. Meanwhile installation of the tram’s Tomlinson couplers continues with one main coupler unit installed under the south cab. Work on refurbishing the north cab bracket – along with brake rigging levers – continues.

[3]

[3] [4]

[4] [5]

[5] [6]

[6]17th December

The coupler for the north cab has been installed, with the majority of current work now focused on brake rigging installation.

January 2023

14th January

The museum’s woodwork crew have fabricated the timber cleats for the car’s trolley pole mounts and hooks tower assemblies.

28th January

The tram has received its first major piece of electrical hardware with Ed and Cameron installing an overhauled compressor governor.

February 2023

4th February

John Baggott has constructed a new access platform for the roof of the car, using a deteriorated example as a template.

11th February

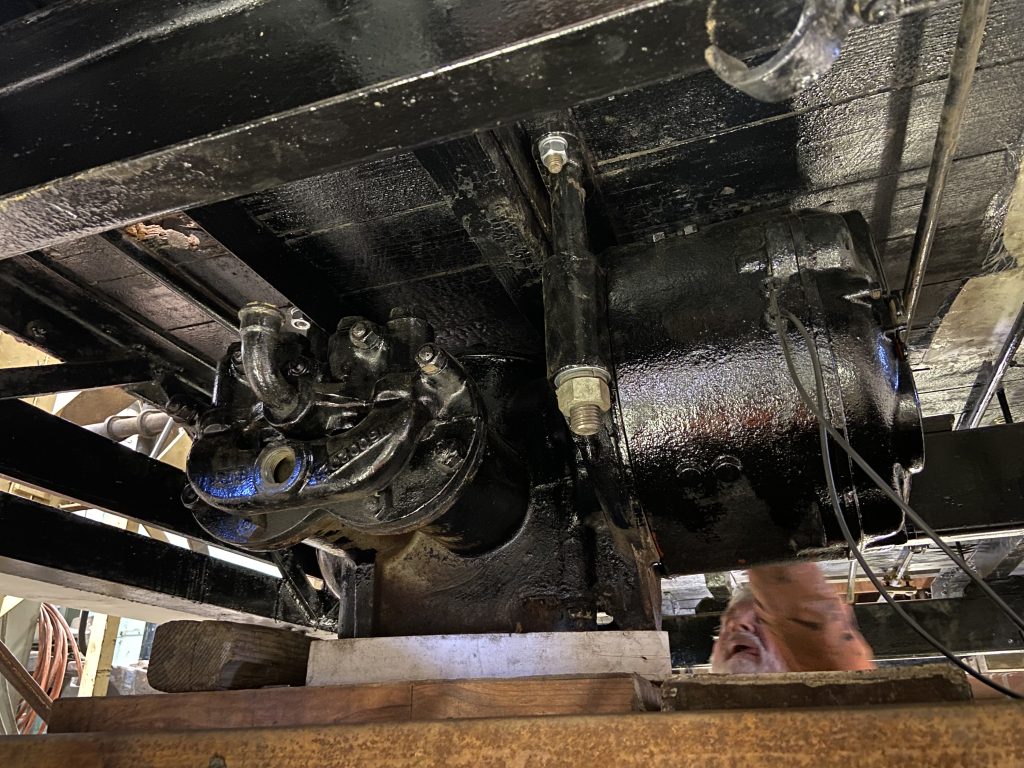

The bogies have been temporarily removed and the tram placed on stands to allow for the cleaning and painting of the underframe before any further equipment is installed.

Rolls of canvas ordered a decade ago during the tram’s initial restoration job were also recovered from the Road 3 pallet racks, with two rolls selected for the future task of pleating the concertina doors.

15th February

A GE compressor that was found to be in good condition in our stockpile has been brought into the workshop for the installation of a motor set. A spare armature and field coil have been overhauled and added to the unit with bench tests proving successful thus far.

18th February

A set of trolley pole hooks have been given a clean up and repaint. A further set will be manufactured offsite for PR1 1573.

22nd February

The GE compressor is complete and will be ready for installation under the tram once appropriate sized stands are sourced. Meanwhile a disassembled 7 inch brake cylinder is being inspected for cleaning and restoration.

March 2023

1st March

The compressor has been given a coat of paint before installation, as has the brake cylinder which is now undergoing overhaul.

[7]

[7] [8]

[8]8th March

New air tanks (main and PC5), trolley pole hooks and trolley base tower brackets have been manufactured at a Wollongong based contractor thanks to a very generous donation towards this project. All have been primed and await painting before eventual installation. The new trolley pole hooks, along with four sets of tower brackets, will be put aside for PR1 1573.

[9]

[9] [10]

[10]11th March

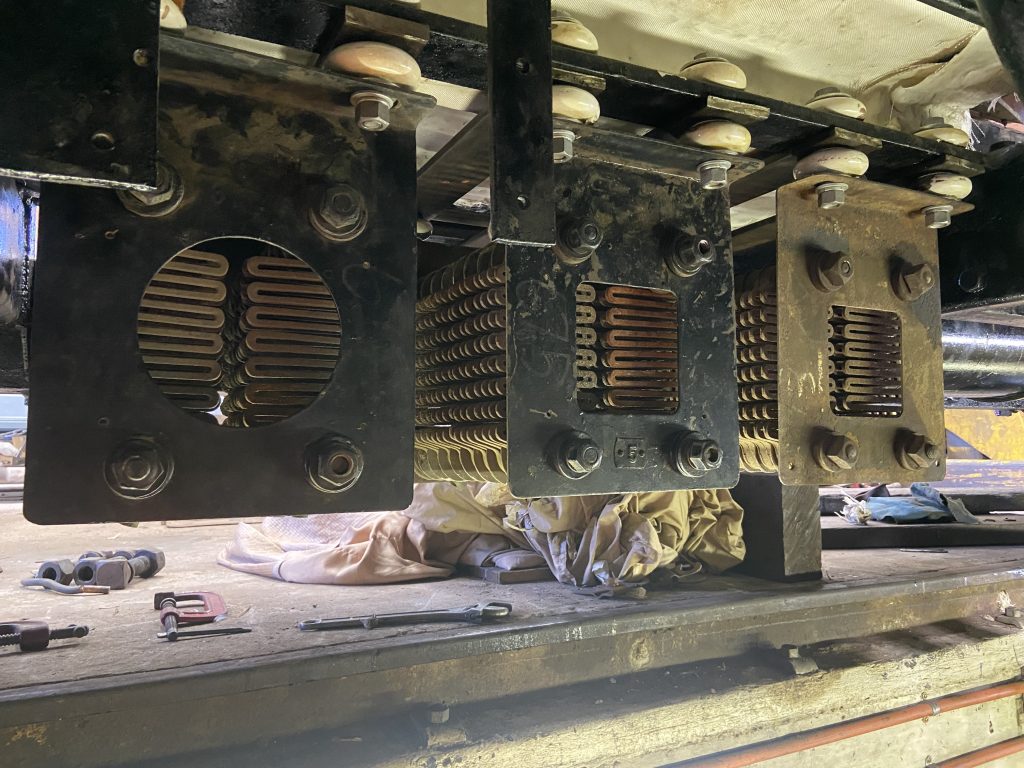

The new tower brackets, hooks and air tanks have been painted in a protective coat of black paint and will be put aside until they can be installed on the car. A palette of resistor grids has also been brought into the workshop with two grids of the correct model selected for overhaul and future installation.

Meanwhile the newly built access platform and end roof slats have been bolted onto the car roof.

29th March

New brackets for the air tanks have been fabricated, test fitted and painted in protective paint by the workshop team.

April 2023

1st April

The smaller PC5 air tank has been installed underneath the car, with only a few remaining adjustments to be undertaken. This will be followed shortly by the installation of the large main tank.

5th April

Installation of the large main air tank has been carried out with successful results. The car now has both sets of air tanks plus a compressor governor installed, with the main compressor unit soon to follow.

[11]

[11] [12]

[12]19th April

The next major piece of hardware is now installed under the car, with the overhauled GE compressor fixed in position this morning. Thus far, the tram has received: couplers, air tanks, compressor, governor and a main fuse unit. It is hoped the PC5 unit and associated terminals/cut outs will follow suit.

[13]

[13] [14]

[14]22nd April

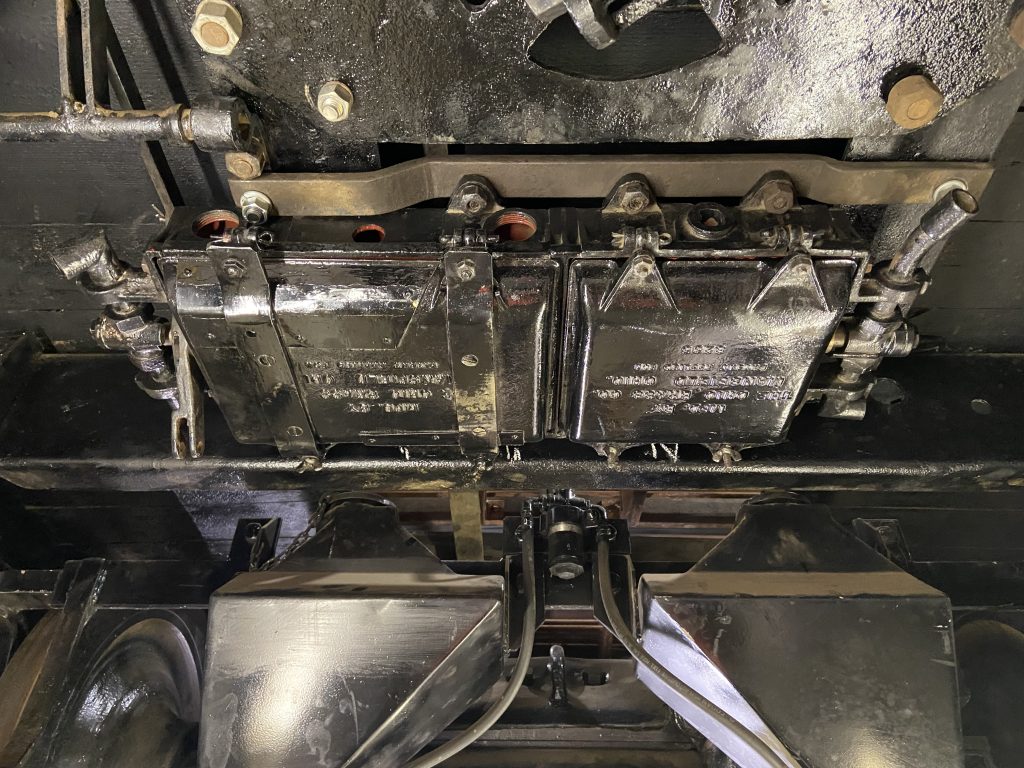

Both the motor cut out unit and motor/trolley connection box from P 1501 are now fixed underneath the car.

[15]

[15] [16]

[16]26th April

Progress continues at a rapid pace with the control connection box now installed next to the motor/trolley connection box.

29th April

Installation of a terminal box is complete with the only remaining items of hardware left to install being the two coupler’s electrical isolation boxes, brake cylinder and PC5 Control unit.

May 2023

3rd May

The previously overhauled PC5 unit has been brought into the workshop for installation under the tram.

6th May

New seals have been delivered for the air brake cylinder, which has allowed for final assembly of the unit to be undertaken. Installation under the car will follow after the PC5 unit is installed.

10th May

The PC5 has been installed underneath the tram, after having electrical insulators attached. P 1729 now has the majority of electrical and mechanical hardware installed, and only awaits the installation of brake piston cylinder, resistor grids and coupler isolation boxes. Before this happens however, the car will be moved out of the workshop temporarily to make way for maintenance work on other museum vehicles. Work on other parts of the tram will continue elsewhere.

[17]

[17] [18]

[18] [19]

[19] [20]

[20]13th May

Progress is being made on new pipework connecting the air compressor with the main air tank.

[21]

[21] [22]

[22]20th May

Due to the need for other tramcar repairs to be undertaken in the workshop, P 1729 has been temporarily moved into the running shed. Utilisation of the Tomlinson couplers was put into action, with P 1497 towing 1729 into Road 3. This is the first time in over 60 years that two cross-bench P class trams have been coupled together in one form or another.

[23]

[23] [24]

[24] [25]

[25] [26]

[26]August 2023

16th August

Motor terminal boxes from P 1501 are in the process of being cleaned, repaired and overhauled for installation under 1729. New lids for three of the boxes are currently being manufactured by our workshop carpenter John Baggott.

19th August

With other outstanding tramcar repairs now complete, P 1729 has been returned to the workshop for its continued restoration to operational service.

30th August

Our workshop crew have restarted work on 1729 almost immediately, with two overhauled coupler isolating switch units now installed under each cab.

September 2023

6th September

The reassembled 7″ brake cylinder has finally been bolted into place under the car. Meanwhile the motor terminal boxes from 1501 await an exterior repaint before installation.

[27]

[27] [28]

[28]9th September

The motor terminal boxes have received their external repaint and await installation.

13th September

A series of window stabilisers from 1501 have been restored to go into 1729. These will help reduce rattling of the car’s windows.

20th September

Two sets of trolley pole bases have been selected from the spare parts stock and are in the process of being descaled and cleaned for repainting. A set of resistor grids has also been selected for the tram.

23rd September

Vic Solomons continues work on cleaning up the trolley pole bases for 1729.

27th September

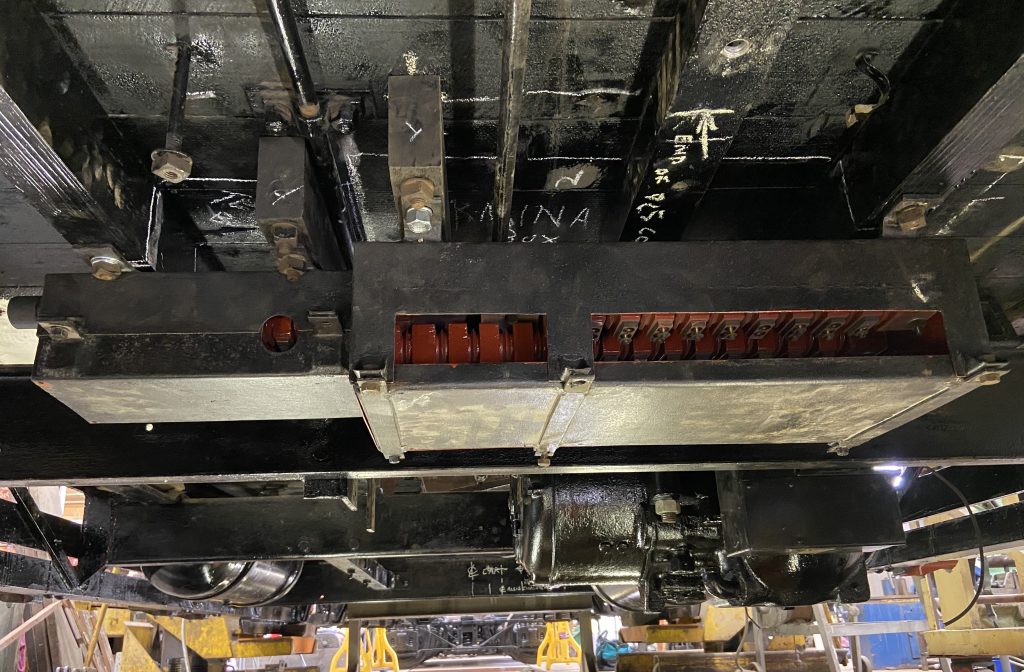

Two out of the three resistor grids to go under 1729 have been installed. Work has also been continuing on tram’s compressed air piping system, with an air intake cock and flexible pipe connecting it to the compressor unit both installed recently.

30th September

All three resistor grids have new been installed. This marks the completion of installation of all underfloor hardware under this car bar motor terminal boxes. Both bogies have also received their full complement of brake shoes; only three were previously installed on one bogie. Progress continues on the restoration of the trolley bases.

[29]

[29] [30]

[30] [31]

[31]October 2023

21st October

The bogies have been removed and the body placed on stands to allow for the installation of motor terminal units and further works on brake rigging and air braking.

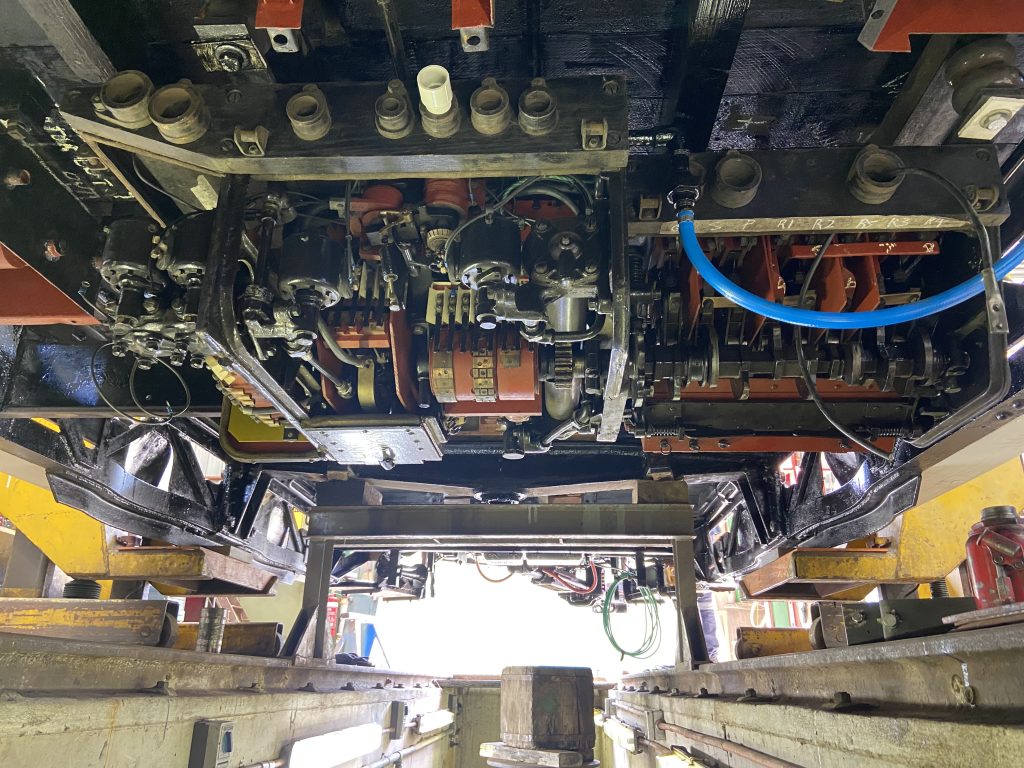

[32]

[32] [33]

[33]25th October

All four motor terminal boxes have now been installed, marking the completion of all hardware installation for this tram. Work continues on air piping and brake rigging.

Interior handrails from P 1501 are being restored for eventual installation in 1729; replacing several missing sets.

November 2023

1st November

The interior components of the motor terminal boxes have been installed.

4th November

The trolley bases allocated for this car have been applied with paint stripper and steam cleaned several times this morning. They are now ready for repainting.

8th-11th November

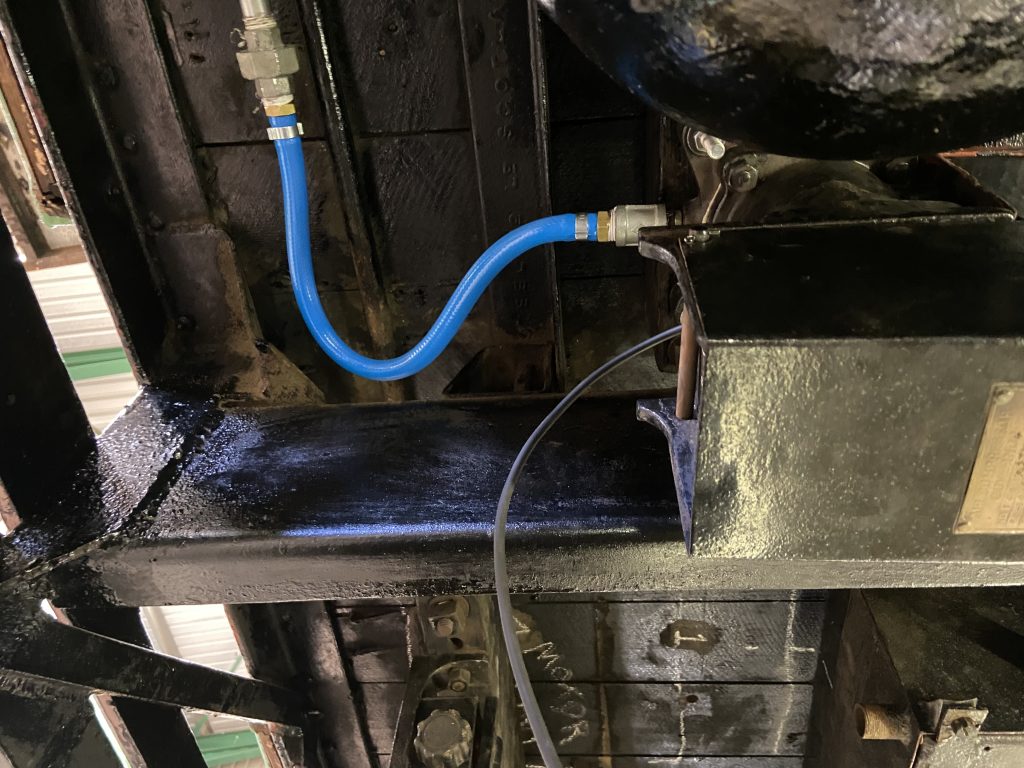

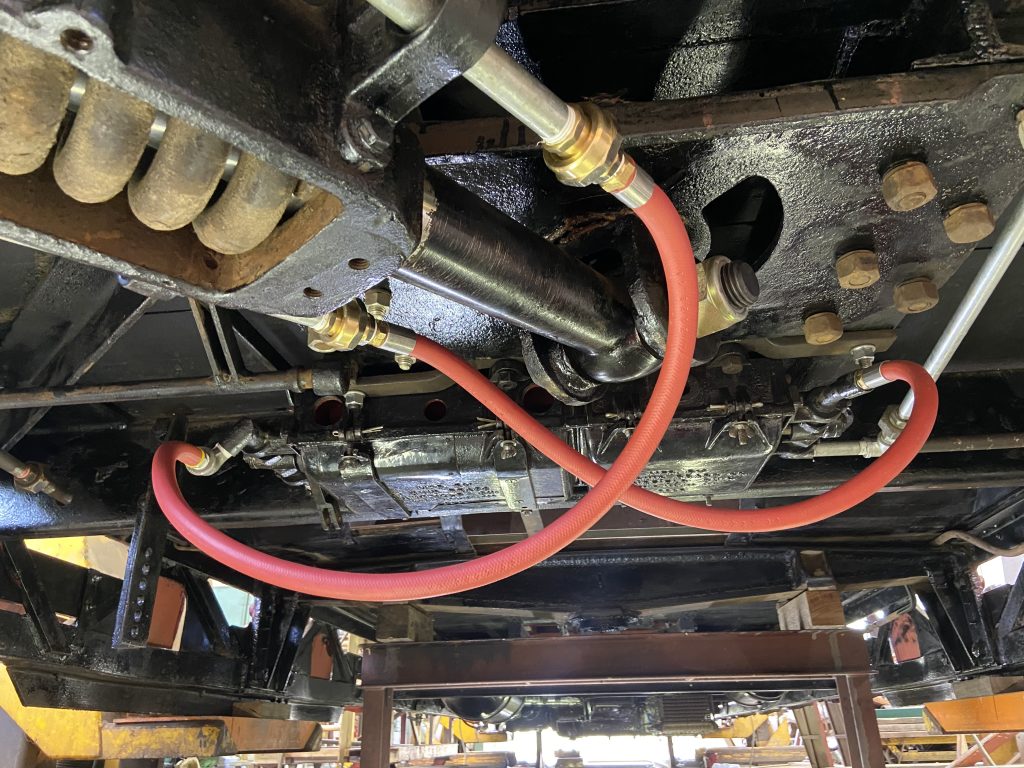

Progress on the air plumbing for this tram is continuing at a rapid pace. New pipe has been cut and threaded where required, with air tanks, piston, compressor governor, and PC5 unit all in the process of being connected to the air brake system. Future works will require the installation of air pipes to pass up through the drivers cabs, connecting with the overhauled air brake valves.

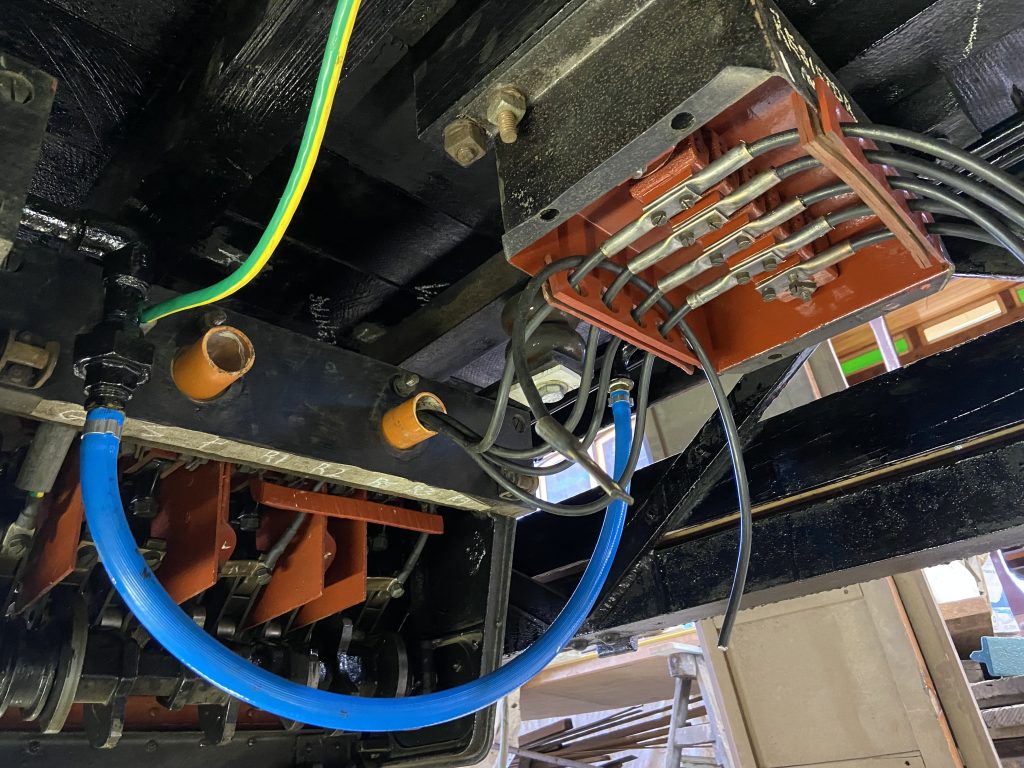

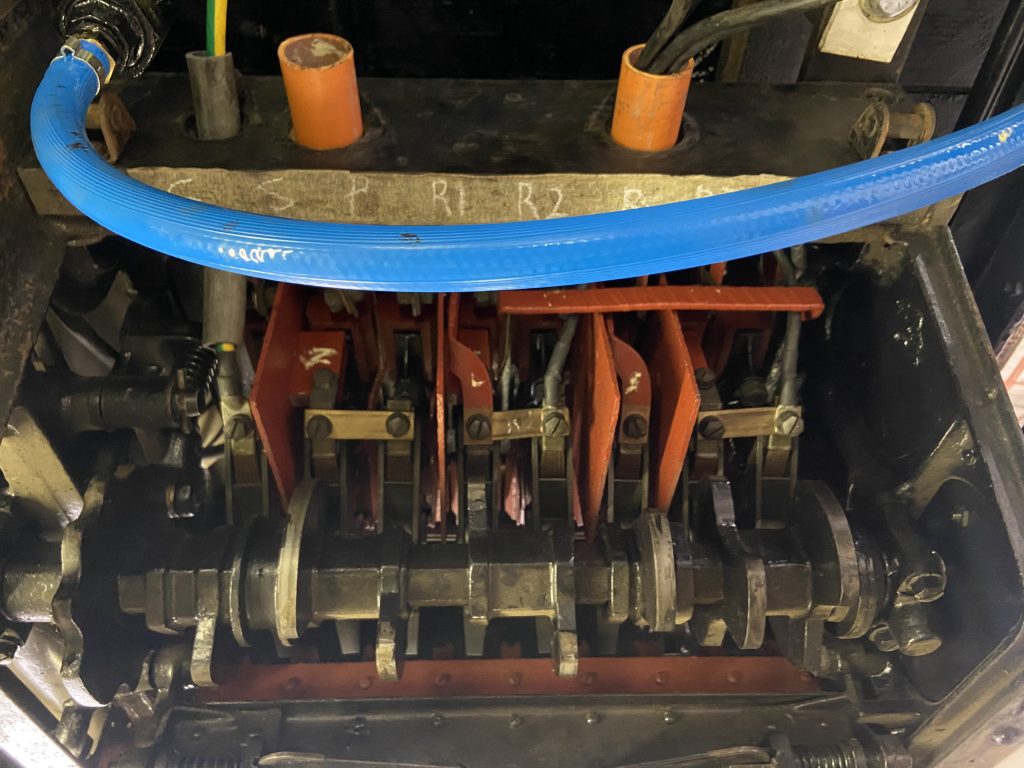

[34]

[34] [35]

[35] [36]

[36] [37]

[37] [38]

[38] [39]

[39]18th November

Trolley bases have been painted and ready for future installation.

22nd November

Primer has been applied to two sets of interior handrails from 1501. A second coat will be applied, before being painted in a white enamel top coat.

[40]

[40] [41]

[41]22nd – 25th November

New air pipes have been cut, threaded and connected to the overhauled manual lap brake valve in the No. 2 end cab.

[42]

[42] [43]

[43]29th November

Progress on the new air brake pipework under the No. 2 end drivers cab. Connection to the rest of the pipework will follow shortly before work begins under the No. 1 end cab.

January 2024

17th January

Work on the airbrake system continues at an advanced rate, with measurements being taken for the connection of pipes to the couplers.

Meanwhile wiring has begun on the roof of the car.

24th January

Flexible pipes are now connected between the couplers and isolating switch units.

February 2024

Air piping and mechanical works have all been completed. Wiring on the roof of the tram continues, with the installation of trolley base and hook stands underway.

March 2024

16th March

Repainting of the centre handrails is mostly complete, with one trial fitted in the car’s middle compartment this morning.

20th March

Wiring underneath the car has begun, with the wiring of the resistor grids to the terminal box.

Work on the cosmetic aspects of the tram continue, with headlight rims being repaired and prepped for eventual installation of headlight fittings and reflectors, along with the continual cleaning and repainting of interior compartment handrails.

April 2024

3rd April

Floors of both drivers cabs have been painted prior to the installation of floor slats. These are still to be manufactured.

6th April

Wiring has commenced between the compressor and governor.

10th April

New floor slats for the drivers cabs prepare to be fitted.

Underfloor wiring continues; the cables connecting the resistor grids to the terminal box have been properly tied together, meanwhile the lids have been removed off the PC5, motor cut out and control connection units, with instructions given by Workshop Manager Bill Parkinson on how to wire up each bit of hardware.

[44]

[44] [45]

[45] [46]

[46]Sanding has begun on the interior roof in preparation for a long awaited repaint.

13th April

The first strands of electrical wiring have been connected between the terminal box and PC5 unit. Different types of conduit fittings have been installed as a test trial.

Meanwhile the floor slats in the drivers cabs have been painted black. Focus now turns to repainting the rest of the cab walls.