Work has commenced on the long-delayed project of wiring up road 13 in our secondary operations building, which will allow for Variotram 2107 – which is stabled in this road – to be powered up and moved out of the shed via overhead power, as opposed to the wondering lead currently used. The first stage of this project – spearheaded by one of our young members Daniel Nguyen, with assistance from Michael Hatton and Infrastructure Manager Danny Adamopoulos – is to restore five sections of depot overhead troughing that the museum has in stock. This troughing was originally donated to the museum in 1980 by the Museum of Applied Arts and Sciences from Ultimo tram depot, with many sections from this donation already used for the overhead in Roads 1, 2, 3, 4 and 12. Each section of troughing selected will go through specific stages of renewal, starting with sanding, two coats of primer then a coat of electrical insulating varnish before assembly, then a final coat of varnishing.

February 2022

4th February

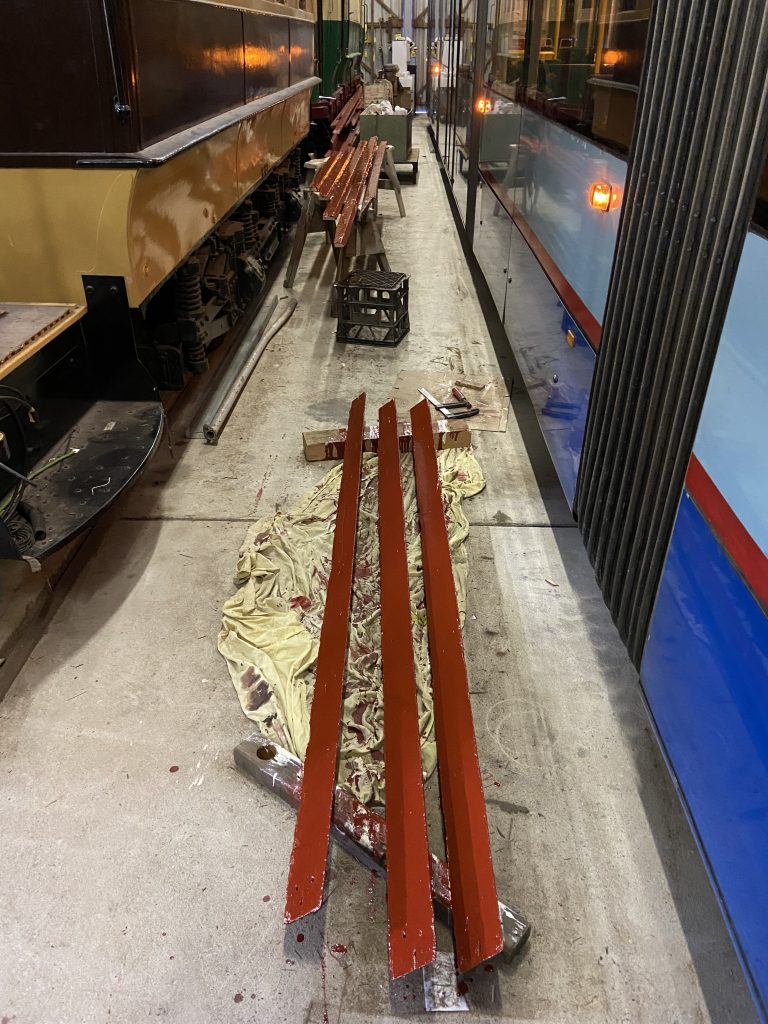

The best sections of troughing have been selected and laid out along the floor of road 13 to determine the final length. Pieces which have rotted ends will be marked and cut accordingly.

12th February

Brackets to support the overhead have been picked out from our stock and labelled.

19th February

The first sections of troughing have been placed on work horses for the beginning of restoration works.

Danny has also put PVC glue on any problematic cracks in the timbers. Once dry the wood will be ready for sanding.

March 2022

12th March

The first set of timbers have received both coats of primer, which will prevent the insulating varnish being absorbed by the wood

19th March

The first coat of insulating varnish has been applied to the troughing.

Meanwhile miscellaneous pieces such as side and triangle timbers have been primed and varnished for future assembly.

26th March

More pieces have been varnished with assistance from young member Nathan Woo. A trial fitting of the first two sections is expected to happen soon.

April 2022

9th April

Trial fitting of loose troughing parts has taken place, which will help determine the cutting and positioning of the various pieces in the final result. Once decided, the pieces will be permanently fitted and the second coat of varnish applied to the entire length of trough.

In the meantime, priming and varnishing of more troughing timbers continues to progress at a steady pace.

16th April

Completed sections of troughing have been labelled and stored for future final fittings. Meanwhile work reaches the halfway mark as the last several sections of troughing are sanded back and primed.

23rd April

Varnish has been applied to the second last piece of main timber troughing, with only one section and several loose pieces left to do before another fit out.

30th April

Several more miscellaneous pieces such as side timbers have been varnished or primed with undercoat.

May 2022

7th May

Progress continues on varnishing and preparing more side pieces.

21st May

More loose troughing pieces have been assembled together as full panels for eventual installation above Road 13.

June 2022

11th June

Works have begun on renewing the final piece of main troughing needed for this project, with splits in the timbers glued and clamped and sanding undertaken on other sections. In the meantime, more side pieces continue to be varnished.

18th June

With the glue now dry on the sections of timber previously split, these sections were sanded off before the first coat of primer was applied. With only another coat plus an application of electrical varnish left to do – in addition to the renewal of more loose pieces – this project is approaching closer to the finish line.

25th June

Both coats of primer have been applied to this piece of troughing, with Michael Hatton applying a coat of electrical varnish to one side shortly after drying. The other side still needs attention. Works will then focus on renewing loose parts for eventual joining.

July 2022

2nd July

9th July

With the main troughing timbers complete, works will now mainly focus on refurbishing enough side timber pieces for eventual assembly. Three pieces have been so far selected and sanded.

23rd July

Daniel has prepared more side timber bits and applied the first coat of primer to all of them. A second coat will be applied soon followed by insulating varnish.

30th July

With both coats of primer now applied, Daniel has applied insulating varnish to one side of the timbers with others to follow next week.

August 2022

6th August

13th August

A further set of side timbers and triangles have been primed and varnished. These are expected to be the last pieces in need of renewal before final assembly of the troughing.

20th August

All troughing parts for the Road 13 overhead have been primed and varnished and are now ready for final assembly.

September 2022

10th September

Danny has assisted Michael and Daniel in assembling more lengths of troughing. Good progress has been made with only two lengths of timber left to be assembled before a final coat of insulating varnish is applied.

16th September

Trial fitting of some overhead holder brackets have been carried out. The bolts for these brackets have been cut down to size on the ends. A final fitting will take place soon.

October 2022

7th October

November 2022

12th November

The final stretch approaches with Danny, Michael and Daniel making good progress on more troughing assembly. Only one panel is left to be put together before a final coat and hanger brackets are made before installation above Road 13.